NEWKer 301H Servo Drive Absolute

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled.

1%

₹99

Out of stock

Category Servo Driver

Product Details

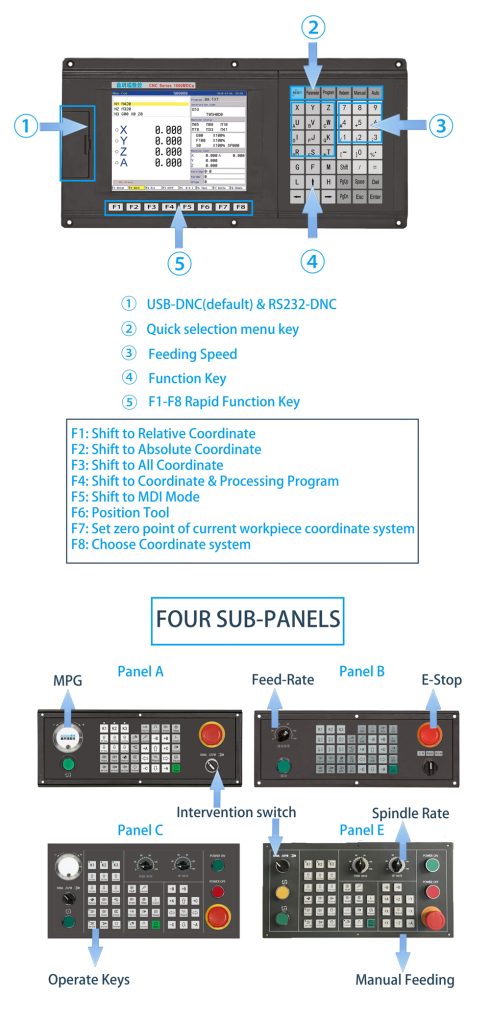

1.Adopt international standard g code 2.Fully open PLC, macro and alarm information 3.Simple HMI (human machine interface), dialog box prompt 4.All parameters are displayed and prompted in English 5.Alarm and error information in words instead of bit parameter 6.Interpolation linkage function of 5 axes and above, RTCP function, DNC function 7.Support Umbrella type ATC, Mechanical hand type ATC, Linear type ATC, Servo type ATC, special type ATC 8.Support counting turret, encoder turret and servo turret 9.The 1000 series and 1500 series have 4 sub-panel models; you can choose according to your needs. 10.NEWKer’s CNC controller also supports the application of various special machines, such as grinding machines, planers, boring machines, drilling machines, forging machines, gear hobbing machines, etc. The controller can also be secondary developed. Support personalized customization and design.

| System Function | G code shows | ||

| Number of control axis | 3~8(X,Y,Z,A,B,C,Xs,Ys) | Locate rapidly: | G00 |

| The smallest programming: | 0.001mm | Straight line interpolation | G01 |

| The most programming: | ±99999.999mm | Arc interpolation: | G02/03 |

| The highest speed: | 60m/min | Thread cut: | G32 |

| Feed speed: | 0.001~30m/min | Cycle of cutting cyliner or cone: | G90 |

| Continuous manual: | one axis or multiple axis at the same time | Cycle of cutting end face: | G94 |

| Line interpolation: | Straight line, arc, screw thread interpolation | cycle of cutting thread | G92 |

| Cutter compensation: | Length of the compansation、radius nose of tool compensation | Fixed cycle of tapping | G93 |

| Cutter compensation input: | Try to cut measuring input mode | Cycle of rough cut in excircle | G71 |

| Spindle function: | gear、Double analog control、Rigid tapping | Cycle of rough cut at end face: | G72 |

| Handwheel function: | panel、handheld | Cycle of closed cut | G73 |

| handwheel processing: | The handwheel processing function | Cycle of drill deep hole at end face | G74 |

| Screen protection: | The screen protection function | Cycle of cutting groove with external diameter | G75 |

| Tool rest function: | Row tool rest、Electric too post 99 knife | Cycle of cutting compound thread | G76 |

| Communication function: | RS232、USB interface | Cycle of program | G22,G800 |

| Compensation function: | Tool compansation、Space compensation、Screw pitch compensation、Radius compensation | Local coordinate system: | G52 |

| Edit program: | Metric/Imperial、Straight thread、taper thread and so on | Detect the instruction of skip | G31,G311 |

| Limit position function | soft limit, hard limit | Pole coordinate | G15,G16 |

| thread function | metric and inch format, straight thread, taper thread and so on | Metrical/Imperial programme: | G20,G21 |

| Preread function: | Preread 10,000 short straight lines | Set coordinate, offset | G184,G185 |

| Password protection: | Multilevel password protection | Workpiece coordinate system: | G54~G59 |

| Input/output: | I/O 56*24 | Tool radius C | G40,G41,G42 |

| PLC programme: | All open PLC design | Accurate locating/continuous path process: | G60/G64 |

| Acceleration and deceleration control: | Straight line、Index | Constant linear cutting: | G96/G97 |

| Number of encoder: | any setting | Feeding mode: | G98,G99 |

| User macro program: | Have | Backing to start point of program: | G26 |

| Electrical gear function: | Have | Backing to the fixed point: | G25,G61,G60 |

| Subpanel | A type with handwheel; B type with band switch; C type with both A and B, E type | Backing to the datum point: | G28 |

| Application: | VMC, grinding, special machine | Suspend: | G04 |

| Macro Program: | G65,G66,G67 | ||

| Auxiliary function: | S、M、T | ||